Factory Boost Jets ??? - Yes and No.

and Controlled Boost Scenarios

Enough posts have been made now that everyone pretty much

knows the "FACTORY BOOST JETS" exist. Well, just to close the case, here

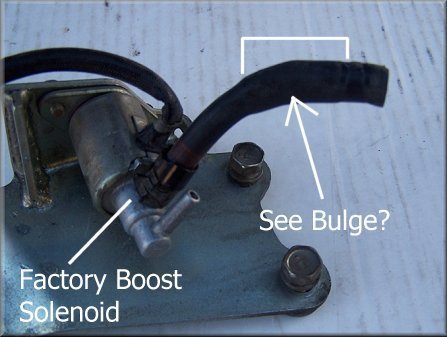

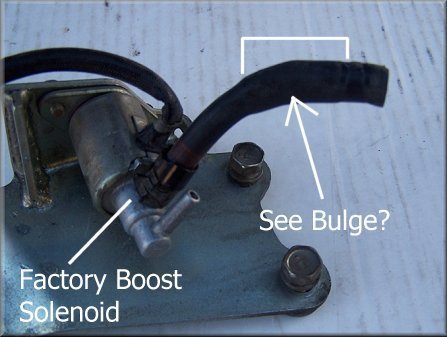

you go. On each side of the car, there are the factory boost solenoids. A

short hose from the intake/inlet pipe (to the turbo compressor inlet)

connects to the "top" (seen on bottom in these pics) port of the solenoid.

This is a vacuum signal and always a vacuum signal. The factory boost

signal hose (comes from front of engine bay from TB pipe nipple) connects

to one other port on the 'T' and the other port has a hose that goes down

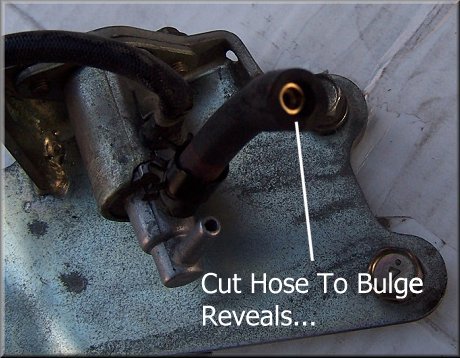

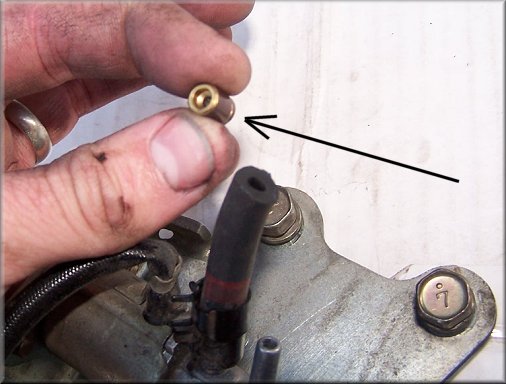

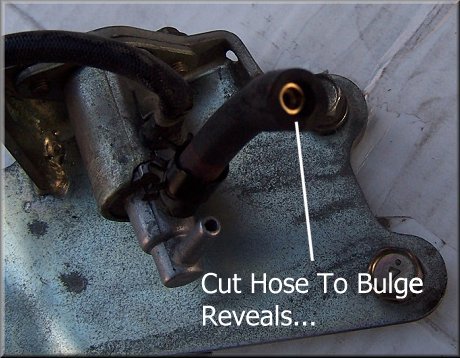

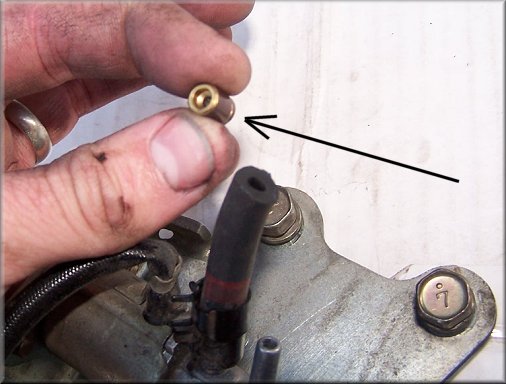

to the turbo actuator. The bottom port of the solenoid has a small section

of hose that then connects to a metal 'T'. On this hose you will find a

bulge. In the bulde is a small restrictor. Note that this restrictor is

not directly inline with the boost signal line, so you could argue that it

is NOT a boost jet, but rather a solenoid signal/vacuum restrictor.

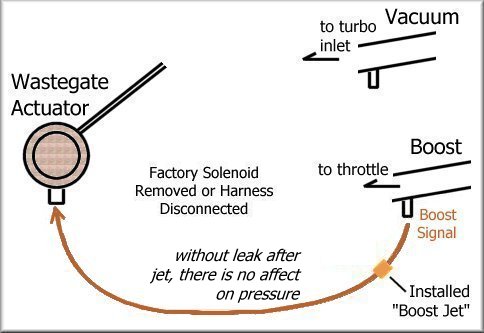

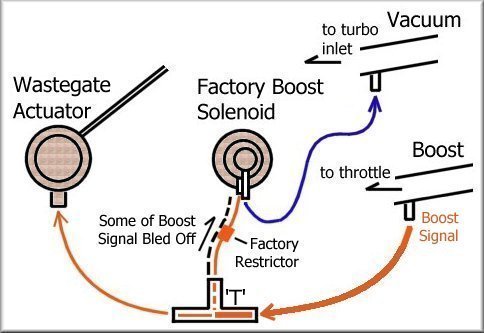

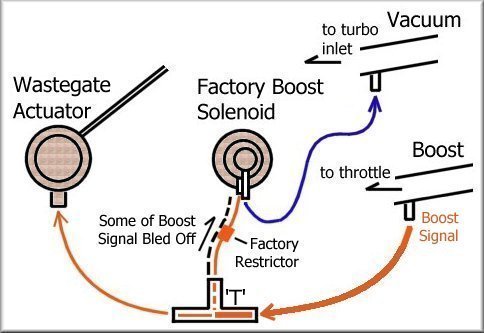

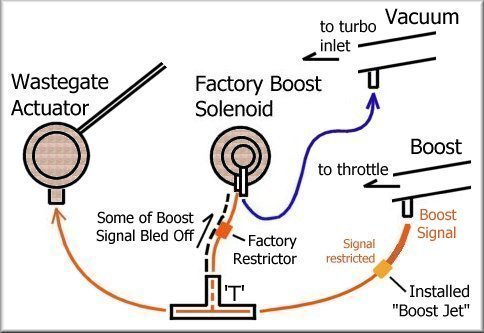

FACTORY SETUP

The factory setup is described in the diagram above. Each

side of the engine has this setup. The wastegate is PRE-SET to open when

seeing a boost signal of about 6-7 psi, while the setup is "calibrated" to

run the engine at about 9-10 psi of boost. When the factory boost solenoid

is OPEN (12v signal) the actual boost signal is bled off through the

solenoid into the intake tract...

So, the wastegate actuator sees less than actual boost

pressure (about 3 lbs less).

If the hole in the restrictor were smaller, the bleed off

would be less...if bigger, more. If you were to plug the line (or remove

the solenoid) and have a direct boost signal, the boost would be limited

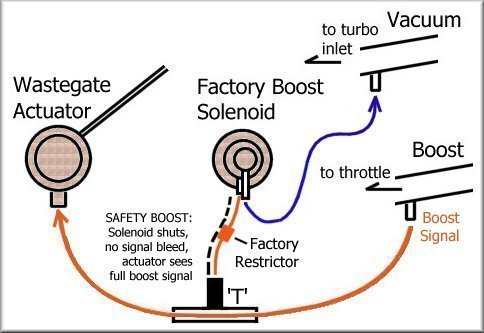

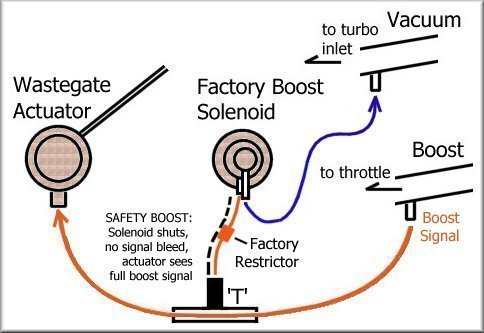

to 7 psi. When the factory solenoid is closed (12v signal cut [safety

boost, cold engine, or startup]), you see about 7 psi max boost because

the actuator is receiving the actual boost signal pressure instead of the

"calibrated" signal.

One problem with this setup is that the wastegate actuator

sees a gradual rise is pressure. While boost is being introduced, the

signal bleeds off incrementally. So, when you are at 8 lbs of boost, the

actuator is seeing 5 lbs and can begin to open. Instead of opening only

when the exact preset level is matched, the operation can be slightly

inconsistent, creating a bit of lag in the spooling of the turbo. This

problem can be solved by using an EBC, as discussed below.

FACTORY SETUP (in SAFETY BOOST)

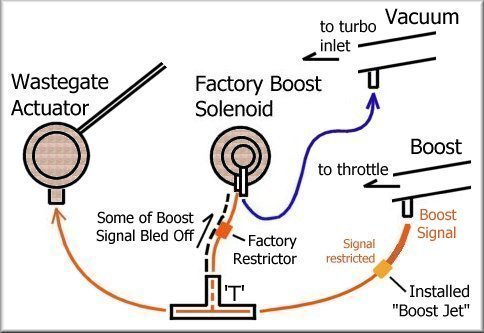

FACTORY SETUP w/AFTERMARKET BOOST JETS

Now then -- you decide to install boost jets into the boost

signal line while keeping the stock solenoids installed. You put in .045

jets and are now running 14 psi. The boost jet is restricting the actual

boost signal, "tricking" the system and showing the actuator less pressure

(boost) than actual boost. The small hole in the boost jet allows less

pressure through the signal hose (about 4-5 psi in this case). The factory

solenoid further bleeds this signal (about 3 psi). The result is that the

actuator sees 6 psi of pressure when in actually you are running 14 psi

into the manifold. Another issue here, the signal is bleeding to the

actuator as boost increases. So, when you're at 10 psi, the actuator sees

2 psi. When at 12, actuator sees 4 psi. The actuator may actually start

moving once pressure is getting close the operating opening pressure, as

in the stock setup (discussed above).

Another issue with boost jets, also seen in the stock setup

(but not as serious), is boost spike. The boost level seen in the engine

can spike for brief moments before the actuator operation opens the

wastegate and holds boost at max. This can be dangerous for the engine,

leading to pre-detonation.

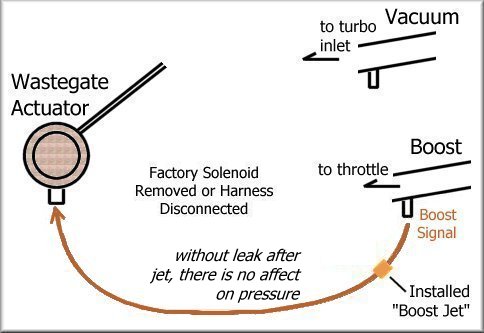

AFTERMARKET BOOST JETS w/FACTORY SOLENOIDS REMOVED

Now, you remove the factory solenoid and connect the boost

signal line directly to the wastegate actuator (or disconnect the

electrical connector). You still have boost jets in the boost signal hose.

What happens now? I was confused about this at first, but then the concept

was explained to me on TT.net. If there is no leak, the pressure on both

sides of the boost jet remains equal, even though there would appear to be

a restriction of flow and less pressure on the other side. So, throwing in

boost jets on a dedicated line to the actuators does NOTHING. However, if

you remove the line or plug it completely, the actuator can never open and

you will hit "infinite boost".

ELECTRONIC BOOST CONTROLLER (EBC) with SOLENOIDS REMOVED (or

unplugged)

Last, you install an EBC. All the sudden there is a

different operation. (not a full or precise explanation, but you can find

out all about EBC's on TT.net). The EBC solenoid provides NO SIGNAL to the

actuator until the precise moment you reach the maximum set boost. What

does this mean? The actuator sees NO PRESSURE and will not start to open

until EXACTLY when full boost is reached, at which point it opens

immediately. The EBC either opens and closes this signal quickly or will

bleed a bit of pressure (like the factory solenoid) to maintain pressure

at exactly what is set. This provides better spooling and quicker boost

response. Advantage EBC.

THERE YOU GO.